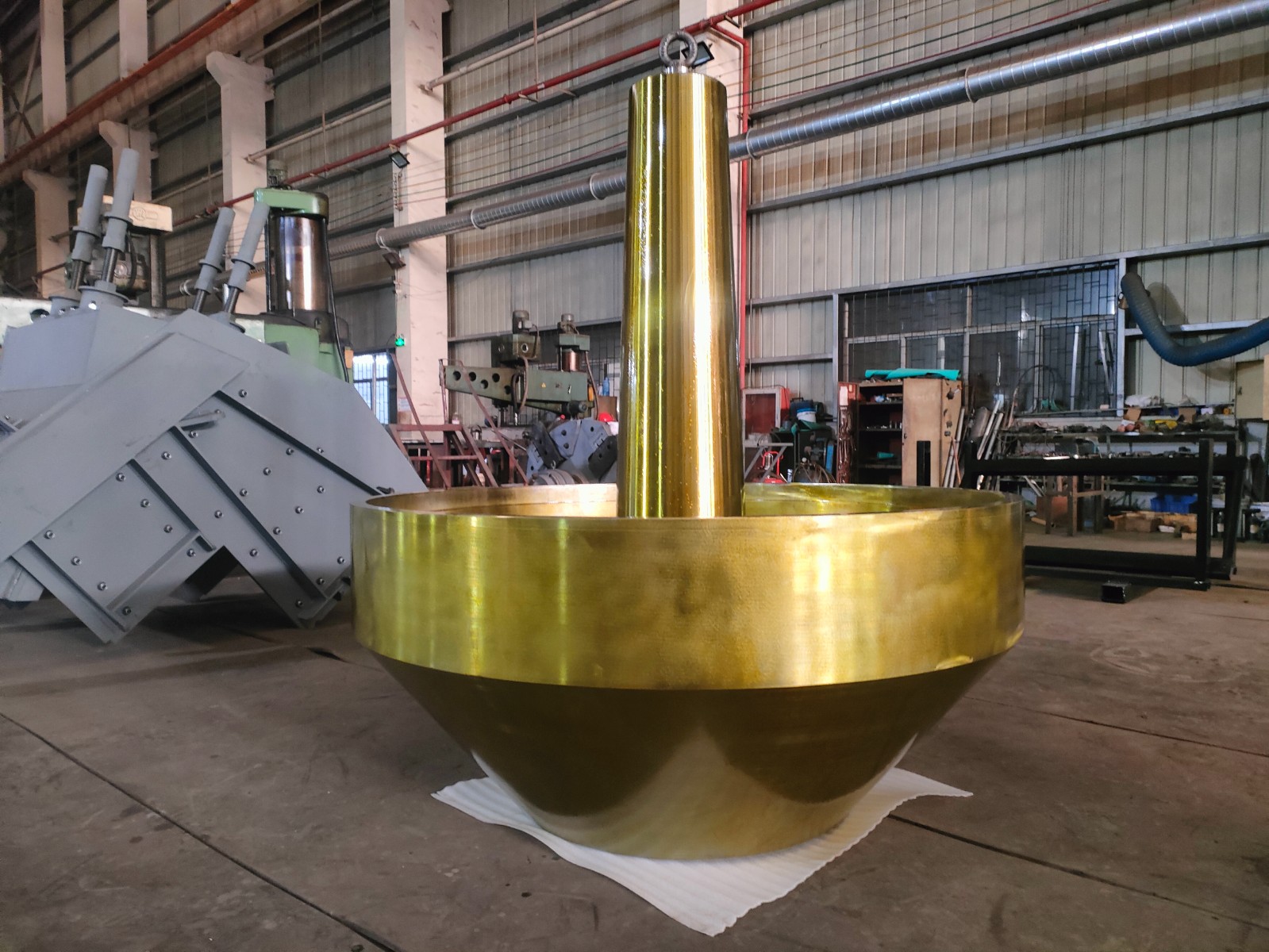

cone crusher spare parts_Spindle cone assembly of our Symons cone crusher.

Our specific model is: Symons 5 1/2 FT cone crusher.

The cone crusher spare parts in question offers several distinct advantages over traditional models, making it a superior choice for industries like mining, construction, and metallurgy. Here's a structured breakdown of its key benefits:

1. Automation & Laminated Crushing of Spindle cone assembly

- Enhanced Efficiency of cone crusher spare parts: Utilizes advanced automation of cone crusher spare parts to dynamically adjust settings (e.g., crusher speed, discharge gap) based on real-time material feedback, optimizing energy use and throughput.

- Laminated Crushing Principle: Progressive crushing through layered compression ensures materials are crushed in stages, reducing energy waste and improving particle consistency. This minimizes over-processing and wear on components.

2. Particle Size Control of Spindle cone assembly

- Uniform Distribution: Optimized crushing chamber geometry (mantle/concave design) ensures even pressure application, yielding consistent particle sizes critical for construction aggregates and industrial processes.

- Reduced Over-Crushing: Prevents excessive fines by precisely controlling compression, enhancing cone crusher spare parts quality and reducing downstream screening needs.

3. Material Versatility of Spindle cone assembly

- Hardness Compatibility of cone crusher spindle cone assembly: Engineered with robust materials (e.g., high-strength alloys) to handle medium-to-high hardness substances (e.g., granite, iron ore), broadening application scope.

- Wear Resistance: Durable components extend service life, even in abrasive environments, reducing maintenance frequency.

4. Operational Stability of Spindle cone assembly

- Low Vibration & Noise: Advanced balancing of rotating assemblies and hydraulic damping systems minimize mechanical stress and noise pollution, aiding regulatory compliance and workplace safety.

- Smooth Performance: Enhanced mechanical design reduces foundation stress, prolonging equipment lifespan and lowering operational costs.

5. Industry Applications of Spindle cone assembly

- Mining/Metallurgy: Efficiently processes hard ores, reducing energy costs and downtime.

- Construction: Delivers uniform aggregate sizes for concrete and asphalt, ensuring structural integrity.

- Environmental Impact: Energy-efficient operation and noise reduction align with sustainability goals of cone crusher spindle cone assembly.

Comparative Edge Over Traditional Crushers

- Proactive Adjustments: Automation outperforms manual systems in maintaining efficiency under variable loads.

- Consistency: Eliminates uneven wear and inconsistent output common in older models.

- Durability: Superior material handling of cone crusher spindle cone assembly reduces part replacement frequency, enhancing ROI.

In summary, this cone crusher spindle cone assembly excels in automation, precision, versatility, and operational reliability, making it a transformative solution for industries demanding high-performance crushing technology.

Carrying forward the spirits of fine workmanship for manufacturing, research, development and innovation

------Dedicating to solutions to the mineral crushing and screening.

we are Shanghai Zhuyan Heavy Industry Technology Co., Ltd

email: shanghaizhuyan@gmail.com

facebook: https://www.facebook.com/shanghaizhuyan/